1. What Constitutes a Booster Compressor?

In industrial settings, common air compressors typically fulfill most pressure requirements.

However, when the need arises for pressure levels beyond the capabilities of a standard compressor, a booster compressor comes into play.

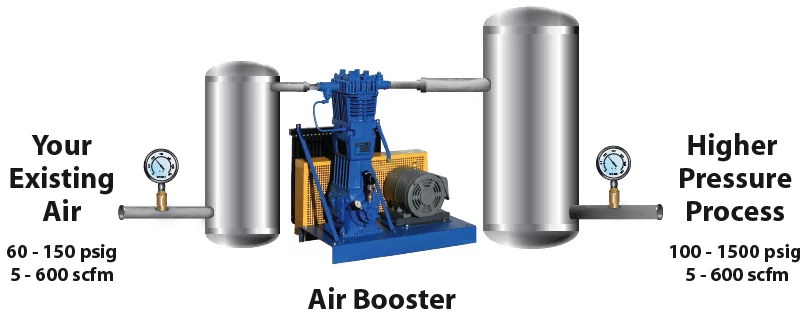

The term “booster compressor” refers to a specialized type of compressor designed to elevate the pressure of the primary feed air compressor.

In essence, a booster compressor is an equipment that augments the pressure of compressed air originating from an existing air compressor.

By introducing an air booster into the system, the compressed air undergoes additional compression stages.

Consequently, a booster compressor can elevate existing air pressures, often ranging from 80-150 psig, to as high as 2000 psig.

2. Elevating Compressed Air Pressure: The Principles

Increasing compressed air pressure can be achieved through three primary methods:

a. Augmenting Gas Quantity: By introducing more gas molecules into the system, the frequency of collisions among air molecules rises, leading to an increase in pressure.

b. Raising Gas Temperature: Elevating the air temperature intensifies the motion between gas molecules, resulting in higher pressure.

c. Reducing Gas Volume: Given the compressible nature of gas, it can be compressed into a smaller container, exerting higher pressure in the process.

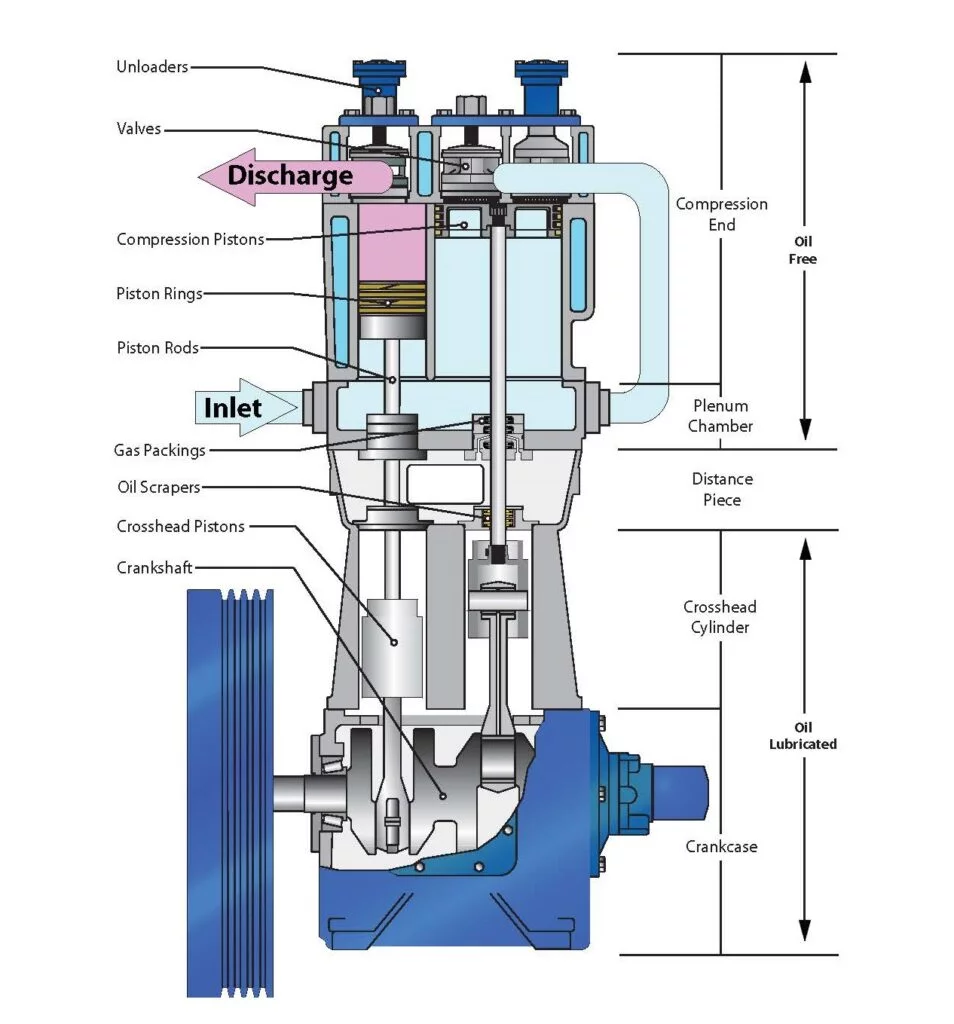

Both air compressors and booster compressors are employed to heighten gas pressure by reducing its volume.

3. Types of Sollant Booster Compressors

As a reputable booster compressor manufacturer, Sollant offers various types of booster compressors to cater to diverse industry needs:

- Oxygen Booster Compressor: A completely oil-free air compressor, requiring no lubricating oil. It’s often used in critical applications like medical oxygen supply.

- Nitrogen Booster Compressor: Widely employed in gas separation processes, particularly in chemical engineering and food production. Nitrogen booster compressors are designed to meet stringent purity requirements.

- CO2 Booster Compressor: This compressor is specifically designed for handling carbon dioxide and is also an oil-free air compression system. It’s commonly used in applications involving CO2 gas.

For those seeking a reliable booster compressor manufacturer, Sollant offers a comprehensive range of solutions, including oxygen booster compressors, nitrogen booster compressors, and CO2 booster compressors.

4. Discerning Compressors from Boosters

As previously discussed, both standard air compressors and booster compressors operate on the fundamental principle that within a closed system, pressure increases as volume decreases.

- Air Compressors: These devices provide pressurized air up to approximately 150 psi, serving as the foundational component of any air compression system.

- Booster Compressors: In contrast, booster compressors function as devices to amplify and raise the pressure of already compressed air to levels as high as 2000 psi. Additionally, booster compressors are integrated into existing compression systems, adding supplementary compression stages for the compressed air’s journey.

In industrial contexts with heightened gas pressure requirements, booster compressors offer an efficient and cost-effective solution compared to designing an entirely new high-pressure compressed air system.

This makes them a valuable asset in applications where precision and performance are paramount.

By Sollant

By Sollant