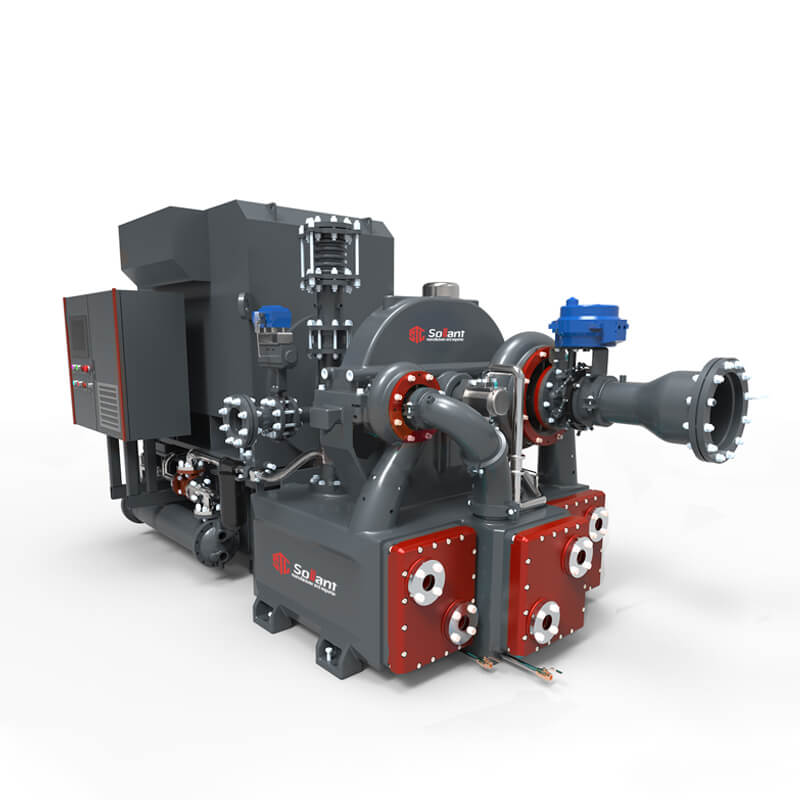

Buying Guide: Centrifugal Variable Frequency Air Compressor

Are you looking to buy a centrifugal air compressor? This article should help make an informed decision because you should consider many aspects of a centrifugal air compressor to ensure you get the best performance. This is a basic guide to centrifugal compressors.

What Is A Centrifugal Air Compressor?

Centrifugal air compressors are also known as dynamic compressors or turbo compressors that have a radial design. Centrifugal air compressors work at a constant pressure to deliver a continuous compressed airflow at every stage. That is why a centrifugal compressor is generally used for refrigerants that requires a combination of low condensing pressure and large displacement. Accordingly, centrifugal compressors are generally used in multiple applications that need a high quantity of compressed air.

How does a centrifugal air compressor work?

Centrifugal air compressors have impellers that increase the velocity of the working fluid through the conversion of kinetic energy into speed. Therefore, the function of the impeller in the centrifugal compressor is to convert kinetic energy into potential energy to create high velocity.

Accordingly, the compressor diffuser and centrifugal unloader valves for air compressors further convert the speed into pressure. Radial centrifugal air compressors generate a higher pressure ratio at a low flow rate. This is the main advantage of centrifugal and axial flow compressors.

The working principle of centrifugal compressors is a bit different from rotary or reciprocating compressors.

There are different types of centrifugal air compressors. However, they all have a basic working principle. Centrifugal compressors operate by the following mechanisms:

- Air is introduced into the centrifugal compressor from the air tank or other sources.

- The air enters the compressor and strikes the impeller with multiple rotating blades.

- Centrifugal force pushes the air into the center of the impeller.

- The impellers increase the speed of air.

- The air is forced into the diffuser, where the speed is significantly reduced.

- The velocity is converted into pressure.

The reduction of the speed of air in the diffuser leads to an increase in pressure. Centrifugal compressors Quizlet should help you understand more about the working mechanism.

What makes a centrifugal air compressor useful?

Centrifugal air compressors are also known as dynamic compressors because they apply Bernoulli’s principle in their working mechanism.

These compressors use impeller discs and diffusers to enhance air compression. The impeller is the rotating element responsible for creating speed. On the other hand, the diffuser reduces speed to increase the pressure of the air.

Centrifugal compressors are the best fit for applications that require more significant flow rates with low specific energy requirements. The design and performance make them cost-effective in the long run.

Centrifugal flow compressors are currently in high demand for many reasons. First, these machines are energetically and mechanically efficient over long duty cycles. Accordingly, centrifugal compressors have higher flow rates and a wide range of rotational speed than other compressors.

Additionally, oil-free and integrally geared centrifugal compressors are excellent for applications that require high-quality compressed air. Other advantages of multistage centrifugal compressors include low maintenance, low running costs, and reliable access.

Centrifugal Compressors Principles Operation and Design

An understanding of the construction and functioning of a centrifugal air compressor is essential. Centrifugal compressors come in different designs, brands, and power generation.

Basically, this centrifugal compressors pdf is designed to offer a complete understanding of the details, functioning, and construction of centrifugal compressors to help you make a sound buying decision. This centrifugal compressor animation should help you understand how these elements work.

Factors to Consider When Buying a Centrifugal Air Compressor

Have you decided between centrifugal vs. axial compressor and centrifugal or reciprocating compressors? If you have already settled on a centrifugal air compressor, here are factors you should consider to ensure you buy the best there is in the market.

- Vertical vs. horizontal split gearbox

Centrifugal compressors rotate at very high speed, which requires the balancing of gears. Horizontal split gearboxes are a more reliable design with low maintenance than vertical split gearboxes.

Since centrifugal air compressors function at very high speed, they need bearings to lower downtime. The best designs that solve problems on centrifugal compressors regarding downtime are hydraulic bearings with the tilting pad design. These bearings are very reliable and easy to maintain. Additionally, you do not have to remove the complete core, unlike other traditional designs.

Centrifugal compressors work on different stages. Due to speed and pressure, the air in every stage should be cooled to enhance agility and performance. Stainless steel offers the best solution than copper since it does not rust.

The best centrifugal air compressors are pre-packed, wired, and connected at the factory. This makes it easy to connect and use. If you want to buy one of these machines, ensure the centrifugal air compressor manufacturer offers integrated packing.

Ensure you choose a centrifugal compressor with cost and energy-efficient features, such as auto-dial, constant pressure control, and blow-off valves. Generally, the machine should guarantee more than 25% turndown below the blow-off. This ensures that it is energy-efficient enough for various applications.

The rotating elements should be designed for different pressure and power variants. An impeller leaning backward is excellent for flexibility and maximizing turndown ratio. The design is also energy-efficient when working with fluctuating power demands.

Easy to install compressor should feature on top of your list. Additionally, you should consider factors such as space and the overall installation costs.

- Maintenance and serviceability

You should go for centrifugal air compressors with a core that is separated from the subframe and cooler. This aspect makes it easier to service and maintain.

Consider a machine designed with an inlet filter and silencer to reduce noise at every compression stage. This aspect ensures a safe working environment.

A centrifugal compressor with a low footprint and is compact is easy to maintain and service. It also saves space during installation.

The last thing you should look at is the brand. There are many brands in the market, including:

- Atlas Copco Centrifugal Compressors

- Baker Hughes Centrifugal Compressors

- Ingersoll Rand Centrifugal Compressors

Ensure you look at every brand separately and compare their centrifugal compressor prices to find the best deal.

Conclusion

There are many types of centrifugal air compressors, making it more challenging to choose the best one for your projects. Accordingly, every brand and type has its ideal applications based

The Guide: Rotary Screw Air Compressor

Rotary Screw Air Compressor applications range from chemical plants to oil and gas refineries and various on-shore and off-shore gas injection applications.

The application of a Rotary Screw Air Compressor leads to a pressure rise by incorporating velocity into a fluid flow. This velocity is then transformed into an increase in static pressure. The device achieves this by interfering with the flow and reducing it down with the help of a diffuser.

The diffuser of the Rotary Screw Air Compressor converts the maximum portion of the flowing air velocity into static pressure.

Centrifugal Air Compressor VS Rotary Screw

Before you purchase an air compressor for your needs, make sure you go through enough resources highlighting centrifugal vs screw air compressors, as it will help you have a better idea of how these tools work.

Rotary screw air compressors, as their name suggests, work with rotation. The rotary screw is responsible for air compression. Notably, rotary screw air compressors are less complex than reciprocating compressors. You can get a better idea of this when you compare rotary screw diagrams with centrifugal compressor diagrams.

While centrifugal air compressors work differently than rotary compressors, they more or less offer similar results. What makes centrifugal air compressors a good choice is they are more efficient and it is also easier to customize them.

How do Rotary Screw Air Compressor work?

Rotary Screw Air Compressor working revolves around converting the energy utilizing multiple steps of compressing and cooling the air. In a Rotary Screw Air Compressor, the pressure developed depends on the continuous conversion of angular momentum.

The application of Rotary Screw Air Compressor leads to large volumes of refrigerant and that too on low pressure. In a Rotary Screw Air Compressor, the pressure ratio is increased by the tip speed of the blade.

Rotary Screw Air Compressor Efficiency

Air compressor efficiency depends on many factors, including the size and type of air compressors. As a general rule, Rotary Screw Air Compressor efficiency hovers between 0.70-0.85, while it lies anywhere between 0.65-0.75 for rotary air compressors.

Types of Rotary Screw Air Compressor

Different types of Rotary Screw Air Compressor are available in the market, including single-stage compressors, multistage Rotary compressors, small Rotary air compressors, etc. We’re going to discuss a few of them down below.

Single Stage Rotary Compressor

Single-stage compressors are among the most popular Rotary-type air compressors that come with a single impeller. The purpose of the impeller is to direct the flow of air. This type of Rotary air compressor also includes a diffuser and guide vanes.

Prominent single-stage Rotary air compressor examples include over-hung compressors, integrally geared compressors, and more.

Multi-Stage Rotary Compressor

Multi-stage Rotary compressors are designed to pass the air through multiple stages. These compressors are used in a wide range of applications.

Multi-stage Rotary compressors are ideal for situations when single-stage compressors are not able to fulfill the desired pressure requirements. Examples include split-casing multi-stage Rotary compressors, bell casing compressors, and pipeline compressors.

Uses of Rotary Air Compressors

Rotary air compressors can be selected for plant air compression and various other air separation applications. They’re also used for transmission and storage of natural gas as well as different gas injection applications.

Rotary Air Compressor Advantages and Disadvantages

In this section, we’re going to highlight centrifugal air compressor advantages and disadvantages.

Pros

- They are light-weight and easy to design and manufacture

- These compressors are ideal for continuous compressed air supply

- Their flow rate is better than conventional displacement compressors

- They are dependable and requires low maintenance

Cons

- Not recommended for high compression

- Changes in the gas composition may cause issues

- Large frontal area

Rotary Air Compressors Parts

A basic Rotary air compressor comes with 4 Rotary compressor parts – inlet, impeller, diffuser, and collector.

Inlet is a simple pipe that is responsible for controlling the flow of air.

The impeller is the Rotary compressor component consisting of multiple blades that increases the energy of the gas.

Diffuser converts the kinetic energy of the gas into pressure by lowering the gas velocity.

As its name suggests, the collector collects the flow and transmits it to a downstream pipe.

Rotary Air Compressor Manufacturers

There are many Rotary air compressor manufacturers in the market that are known for high-accuracy products. We’re going to highlight a few of them in the following section.

Atlas Copco Rotary Air Compressor

Atlas Copco is a renowned Rotary compressor manufacturer which was established back in 1873. The company is currently working in 180+ countries. Their product range includes air compressors, mining and construction tools, etc.

Ingersoll Rand Rotary Air Compressor

Ingersoll Rand is another famous centrifugal compressor manufacturer that also boasts a diversified portfolio of selling rotary screw, lubricated, and oil-free compressors. Apart from that, they manufacture HVAC systems, refrigeration solutions, and other commercial and industrial systems.

Samsung Rotary Air Compressor

Samsung also produces a wide range of oil-free Rotary compressors. Their SM/SM100/SME series has specifically gained popularity among industrialists around the globe.

Sulzer

Sulzer is a popular engineering and manufacturing brand that is presently operating in 150+ countries. The brand offers a wide range of high-power compressors, including XTA & XTAK aerators and HSR and HST turbocompressors.

Doosan

Doosan has managed to earn and manage its reputation as an industry leader since 1896. Today, the compressors produced by Doosan are widely used in numerous industrial and commercial factories in more than 38 countries.

Things to Consider Before Buying a Rotary Air Compressor

Buying a Rotary air compressor is a long-term business decision. Since compressors are pricey, you must do your research first before investing in any product available in the market.

The web is crowded with Rotary air compressor pdf guidelines that also include centrifugal air compressor diagrams and details about centrifugal air compressor calculations to help you evaluate the centrifugal air compressor efficiency.

It is also critical to compare the prices of different products and see which specific model and brand offers the best value for your money.

Last but not least, always purchase your compressor from the best centrifugal air compressor manufacturers – preferably those who hold quality assurance certifications.