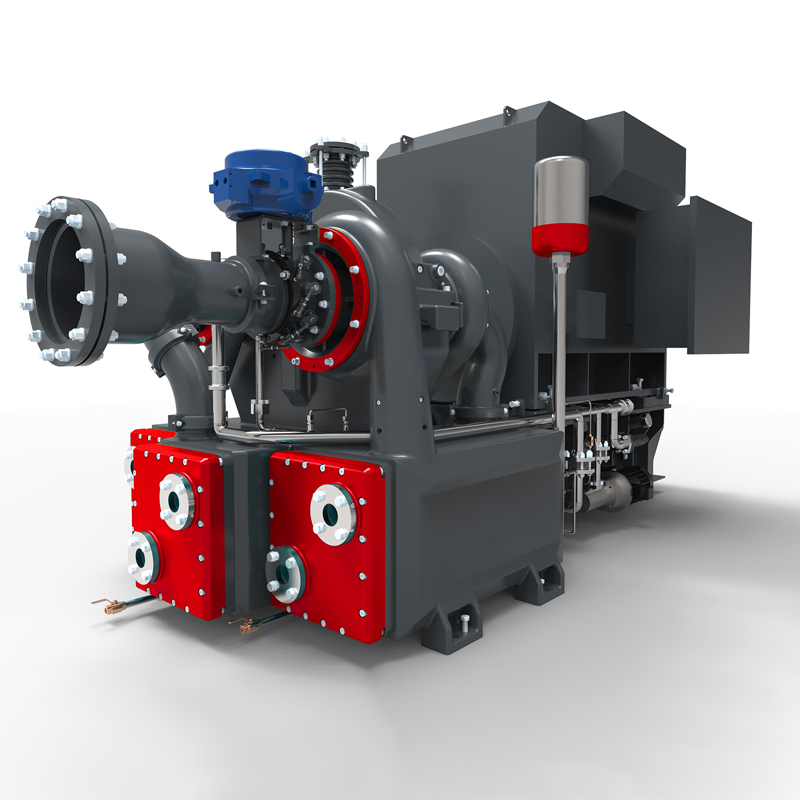

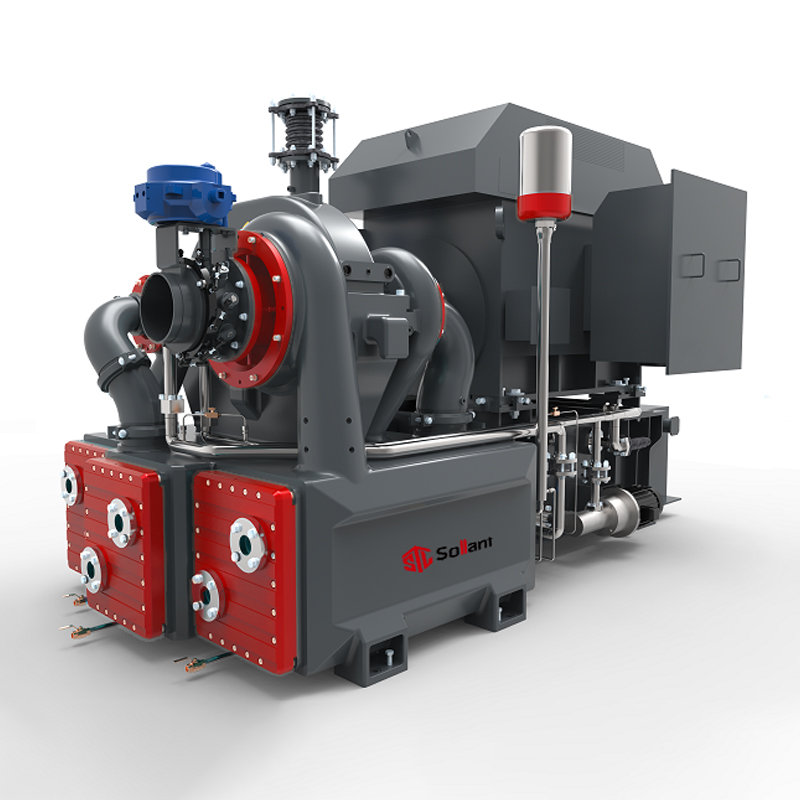

Diaphragm compressors are a type of positive displacement compressor used to increase the pressure of gases or gas mixtures.

They work on the principle of using a flexible diaphragm or membrane to separate the gas being compressed from the compression chamber.

Here’s a basic overview of how diaphragm compressors work:

- Compression Chamber: Diaphragm compressors consist of a compression chamber where the gas to be compressed is contained. This chamber is usually a cylinder with an inlet and an outlet.

- Diaphragm: The key component of a diaphragm compressor is the flexible diaphragm or membrane. This diaphragm is typically made from a strong and flexible material such as metal or synthetic rubber. It separates the gas to be compressed from the hydraulic fluid (usually oil) that is used to actuate the diaphragm.

- Inlet and Outlet Valves: Diaphragm compressors have one-way inlet and outlet valves that allow the gas to enter and exit the compression chamber. These valves ensure that the gas flows in the desired direction.

- Compression Cycle: a. Suction (Intake): In the beginning of the compression cycle, the diaphragm is in its downward or extended position. The gas to be compressed enters the compression chamber through the inlet valve as the diaphragm moves downwards, creating a low-pressure area in the chamber.

b. Compression: The diaphragm then moves upward, reducing the volume of the compression chamber. As the volume decreases, the gas is compressed, causing its pressure to rise. The diaphragm, being flexible, can accommodate this change in volume by flexing or curving.

c. Discharge: When the diaphragm reaches its maximum upward position, the gas reaches its maximum pressure. The outlet valve opens, allowing the high-pressure gas to exit the compression chamber.

- Hydraulic Actuation: The diaphragm is moved by hydraulic fluid, which is usually oil. This hydraulic fluid is pressurized on one side of the diaphragm, causing it to move in the opposite direction, compressing the gas on the other side.

- Cycle Repeats: The compression cycle repeats continuously as the diaphragm moves up and down, creating a steady flow of compressed gas.

Diaphragm compressors are known for their ability to handle a wide range of gases, including corrosive and toxic gases, because the gas being compressed is completely isolated from the mechanical components.

They are often used in applications such as gas transfer, gas storage, and high-purity gas production in industries like chemical processing, petrochemical, and pharmaceutical manufacturing.

By Sollant

By Sollant