Diaphragm compressors are a class of positive displacement compressors renowned for their ability to handle various gases, including those that are toxic, flammable, or high-purity.

These compressors are widely used in industries such as petrochemical, pharmaceutical, and manufacturing, where precise pressure control and gas purity are critical.

In this in-depth exploration, we delve into the mechanics and principles behind diaphragm compressors, unraveling their operation and applications.

Introduction to Diaphragm Compressors

A diaphragm compressor, also known as a membrane compressor, is a type of positive displacement compressor that employs a flexible diaphragm to displace gas and increase its pressure.

Unlike conventional piston compressors, which use reciprocating pistons to compress gas, diaphragm compressors rely on the expansion and contraction of a flexible diaphragm to achieve compression.

These compressors are highly regarded for their unique attributes, making them suitable for a wide range of applications, from compressing hazardous gases to producing ultra-high-purity gases for the semiconductor industry.

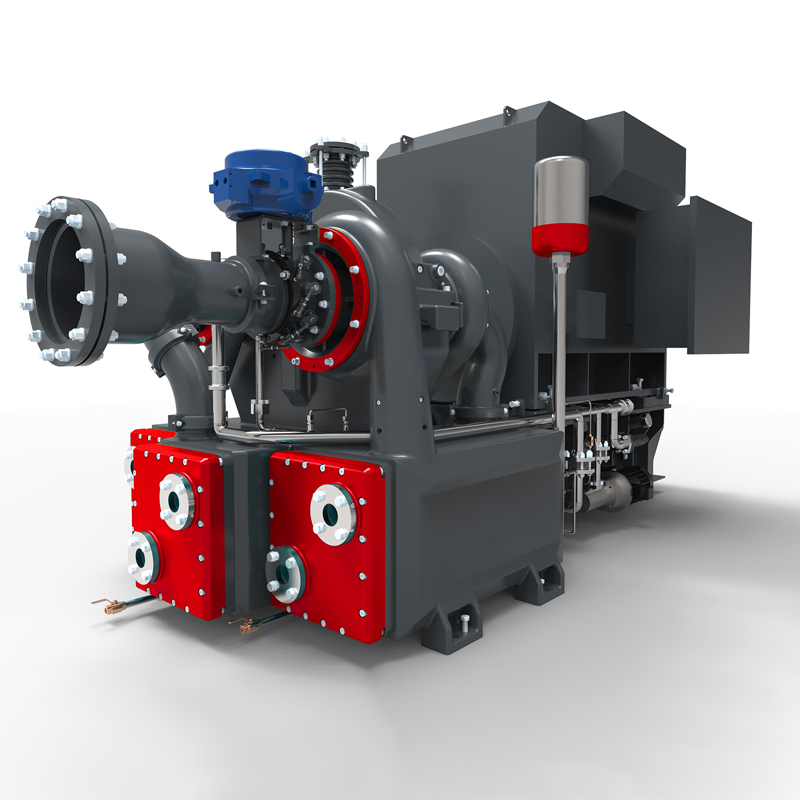

Basic Components of a Diaphragm Compressor

Before delving into the working principles, let’s familiarize ourselves with the essential components of a diaphragm compressor:

1. Diaphragm:

The diaphragm is the heart of the compressor.

It is a flexible, airtight membrane typically made of materials like rubber, elastomers, or metallic alloys.

The diaphragm separates the compression chamber from the hydraulic fluid chamber.

2. Compression Chamber:

This is the region where gas is compressed.

It is enclosed by the diaphragm and one or more check valves, which ensure that gas flows in only one direction during compression.

3. Hydraulic Fluid Chamber:

The hydraulic fluid chamber surrounds the diaphragm. It is filled with hydraulic fluid, typically oil or water, and its pressure is controlled to expand or contract the diaphragm, driving the compression process.

4. Check Valves:

Check valves, often referred to as inlet and outlet valves are responsible for directing the flow of gas into and out of the compression chamber.

They ensure that gas enters only when the diaphragm contracts and exits when it expands.

5. Drive Mechanism:

A drive mechanism, usually an eccentric crankshaft, is used to reciprocate the diaphragm by converting rotary motion into linear motion.

6. Pressure Gauges and Controls:

These components help monitor and control the compression process, ensuring that the desired pressure levels are achieved and maintained.

Working Principles of Diaphragm Compressors

Now, let’s unravel the working principles of diaphragm compressors step by step:

1. Suction Stroke (Diaphragm Expansion):

- The diaphragm compressor begins the compression cycle with the diaphragm in its most extended position.

- The inlet check valve opens, allowing gas from the source to enter the compression chamber.

- Simultaneously, the hydraulic fluid chamber’s pressure decreases, causing the diaphragm to expand and create a larger volume within the compression chamber.

- As the diaphragm expands, it creates a partial vacuum in the compression chamber, causing gas to be drawn into the chamber.

2. Compression Stroke (Diaphragm Contraction):

- With the compression chamber filled with gas, the hydraulic fluid chamber’s pressure increases.

- The inlet check valve closes to prevent backflow, trapping the gas in the compression chamber.

- The hydraulic fluid chamber’s pressure acts on the diaphragm, causing it to contract and reduce the volume of the compression chamber.

- As the diaphragm contracts, it compresses the gas within the chamber, raising its pressure significantly.

3. Discharge Stroke (Gas Expulsion):

- As the diaphragm reaches its fully contracted position, the outlet check valve opens, allowing the pressurized gas to exit the compression chamber.

- The gas is expelled from the compressor at the desired pressure and directed to the application or storage.

4. Restoring the Diaphragm:

- After completing the compression stroke, the diaphragm compressor undergoes a suction stroke again as the diaphragm returns to its extended position.

- The cycle then repeats to maintain the desired pressure levels.

Key Characteristics and Advantages of Diaphragm Compressors

Diaphragm compressors offer several distinct advantages and characteristics that make them suitable for a wide range of applications:

1. Leak-Tight Operation:

Diaphragm compressors provide leak-tight operation, ensuring that the gas being compressed remains uncontaminated and isolated from the hydraulic fluid. This is crucial in applications requiring high-purity gases or those involving toxic or hazardous substances.

2. Compatibility with Various Gases:

These compressors can handle a diverse range of gases, including corrosive, flammable, and high-purity gases. This versatility makes them invaluable in industries such as chemicals, petrochemicals, and semiconductor manufacturing.

3. Pulsation-Free Compression:

Diaphragm compressors deliver pulsation-free compression, producing a steady and consistent flow of compressed gas. This is essential in applications where pressure stability is critical, such as analytical instruments and laboratory equipment.

4. Minimal Maintenance:

Due to their simple design and lack of dynamic seals, diaphragm compressors typically require minimal maintenance compared to other compressor types. This reduces downtime and operational costs.

5. High Pressure Ratios:

Diaphragm compressors can achieve high pressure ratios, making them suitable for applications requiring compression to ultra-high pressures.

6. Contamination-Free Compression:

The isolation of the compression chamber from the hydraulic fluid ensures that the compressed gas remains uncontaminated. This is vital in industries like pharmaceuticals and food processing.

7. Safe Handling of Hazardous Gases:

Diaphragm compressors are well-suited for handling hazardous and toxic gases, thanks to their leak-tight operation and gas isolation.

Applications of Diaphragm Compressors

Diaphragm compressors find application in a wide array of industries due to their unique capabilities and advantages. Some notable applications include:

1. Semiconductor Manufacturing:

Diaphragm compressors are used to produce high-purity gases required for semiconductor fabrication processes. They provide reliable gas compression without contamination.

2. Chemical and Petrochemical Industries:

In chemical processing, diaphragm compressors handle corrosive gases and provide the necessary pressure for various reactions. They are also used to transfer toxic or flammable gases safely.

3. Pharmaceuticals:

Pharmaceutical manufacturing requires precise control of gas purity. Diaphragm compressors ensure the production of high-purity gases for drug manufacturing and research.

4. Laboratory and Analytical Instruments:

Pulsation-free compression is crucial in laboratory equipment. Diaphragm compressors are used in gas chromatography, mass spectrometry, and other analytical instruments.

5. Oil and Gas:

Diaphragm compressors play a role in natural gas gathering, where they compress raw natural gas for transportation to processing facilities.

6. Aerospace:

In aerospace applications, diaphragm compressors provide high-pressure air for aircraft systems and propulsion.

7. Environmental Testing:

These compressors are used in environmental chambers for simulating various conditions, such as temperature and pressure, for testing purposes.

Conclusion: The Versatile and Reliable Diaphragm Compressor

Diaphragm compressors are engineering marvels that excel in applications where gas purity, leak-tightness, and precise pressure control are paramount.

Their ability to handle a wide range of gases, from hazardous to high-purity, makes them indispensable in industries ranging from semiconductor manufacturing to pharmaceuticals and petrochemicals.

The fundamental operation of diaphragm compressors, driven by the expansion and contraction of a flexible diaphragm, ensures that the gas being compressed remains uncontaminated and pulsation-free.

These compressors contribute to the reliability, safety, and efficiency of critical processes across various sectors, making them a vital component of modern industry.

By Sollant

By Sollant